how to control Good quality for manufacture power sockets ?

Controlling good quality for the manufacture of power sockets involves several steps that ensure the safety, reliability, and longevity of the product. Here's how you can maintain high-quality standards during production:

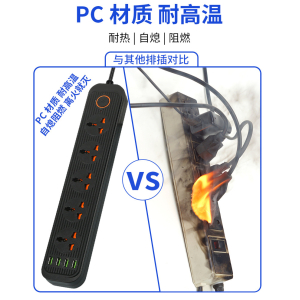

Raw Material Sourcing: Use high-quality materials for all components, including the conductive parts, insulators, and cable jackets. The materials should be able to withstand the electrical and environmental stress expected during use.

Design Review: Ensure that the design meets all relevant safety standards and regulations. This includes proper spacing between outlets to prevent overloading and the inclusion of safety features like surge protection and circuit breakers.

3C Certification Compliance: Adhere to the "3C" (China Compulsory Certification) standards, which are mandatory for products sold in China. This certification ensures that the product has been tested and meets certain quality and safety criteria.

Manufacturing Process Control: Implement strict quality control measures at every stage of the manufacturing process. This includes regular inspections and testing of the components and finished products.

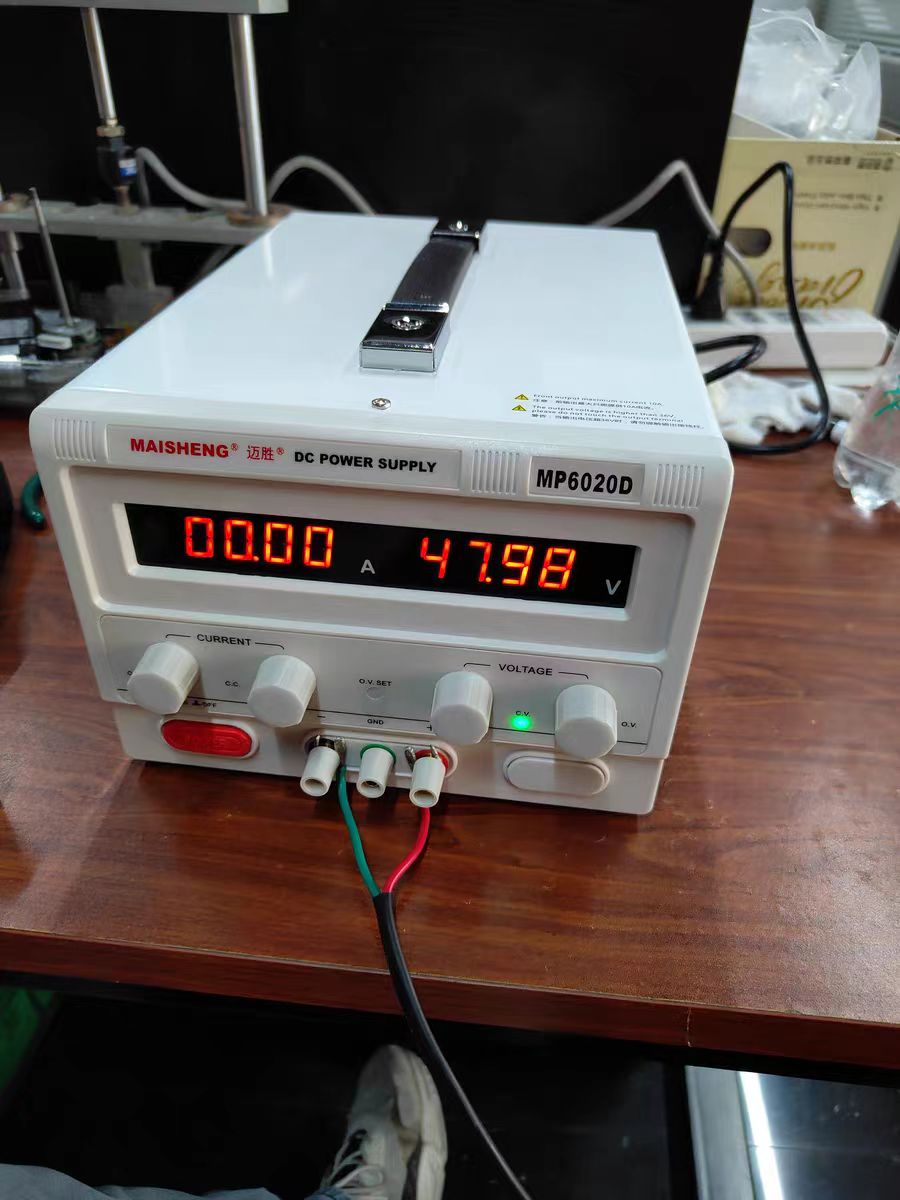

Testing Protocols: Conduct thorough testing, including electrical safety tests, load tests, and endurance tests. Each power socket should be tested to ensure it can handle the rated current and voltage without overheating or failing.

Workforce Training: Train employees on the importance of quality and the specific requirements for manufacturing power sockets. A well-trained workforce is essential for maintaining high-quality standards.

Quality Management System: Establish a robust quality management system (QMS) that includes documentation, regular audits, and continuous improvement processes.

Supplier Management: Work closely with suppliers to ensure they meet the quality standards required for the components they provide.

Product Marking and Labeling: Clearly mark and label each power socket with its specifications, including voltage, current rating, and any certifications it has obtained.

Traceability: Maintain records that allow for the traceability of each unit produced, from the raw materials used to the final product testing and distribution.

Customer Feedback: Listen to customer feedback and use it to make improvements in design and manufacturing processes.

Continuous Improvement: Regularly review and update your quality control processes to incorporate new technologies, feedback, and industry best practices.

Regulatory Compliance: Stay updated with the latest regulatory requirements and ensure that all products comply with national and international standards.

Packaging and Shipping: Ensure that the packaging is robust enough to protect the power sockets during shipping and storage, and that it includes all necessary warnings and instructions for use.

By focusing on these areas, manufacturers can ensure that the power sockets they produce are of good quality, providing safe and reliable service to consumers.